For small and mid-sized palm oil processors looking to enter global markets, choosing the right refining equipment isn’t just about cost—it’s about consistency, quality, and scalability. In this guide, we break down how enterprises like those in Malaysia, Indonesia, and Nigeria are achieving stable output with efficient setups—without over-investing in oversized machinery.

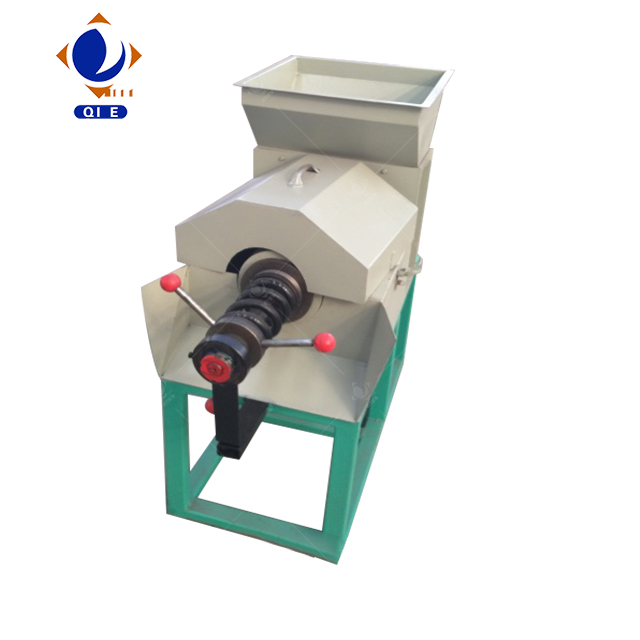

The journey from raw palm fruit to refined edible oil involves three critical stages:

| Stage | Key Parameters | Impact on Output |

|---|---|---|

| Pressing (Crude Extraction) | Temperature: 75–85°C | Moisture Content: ≤10% | +12% yield when optimized vs. substandard pressing |

| Filtration (Clarification) | Filter mesh: 10–30 µm | Pressure: 0.2–0.5 MPa | Reduces free fatty acids by up to 30%, improves shelf life |

| Deodorization | Temp: 220–250°C | Vacuum: 0.5–2 mbar | Removes odor compounds while preserving tocopherol levels |

These parameters aren't arbitrary—they’re based on real-world data collected from over 50 successful installations across Southeast Asia and Africa. For instance, one Malaysian processor increased their monthly export volume by 22% after switching to a modular deodorizer system that reduced downtime by 40%.

Whether you're running a 2-ton/day or 10-ton/day facility, here's what works best:

Our client in Ghana, who previously struggled with inconsistent viscosity, now ships certified palm oil to Europe using a 6-ton/day setup with integrated moisture control sensors—an upgrade that cut rejections by 67%.

Q: Can I scale my current line later?

Yes—if you start with modular components like our standard 3-unit system (press → filter → deodorizer), adding capacity is as simple as integrating an extra module. Most clients expand within 6–12 months.

Q: How do I ensure compliance with international standards?

Choose equipment designed for ISO 22000 and HACCP compliance. Our systems include built-in temperature loggers, batch tracking, and digital SOPs—key for audits by buyers in the US, EU, and UAE.

This isn’t just about buying machines—it’s about building a production culture where precision meets purpose. Whether you’re entering your first export market or optimizing an existing line, the foundation starts with understanding how each piece interacts with the next.

Ready to build your export-ready palm oil line?

Explore our proven small-scale refining solutions tailored for global standards.

Get Your Customized Refinery Layout Plan