In the world of palm oil processing, small - scale producers often face the challenge of achieving high - quality products with limited resources. This article aims to provide a comprehensive guide to the small - scale palm oil refining process, focusing on the deacidification step and how optimizing certain parameters can significantly enhance production efficiency and product quality.

The small - scale palm oil refining process consists of several crucial steps, including pretreatment, degumming, deacidification, bleaching, and deodorization. Each step plays a vital role in removing impurities and improving the oil's quality. Among these, deacidification is particularly important as it directly affects the oil yield and the final product's stability and taste.

The deacidification process is highly dependent on three key parameters: temperature, pressure, and time. By adjusting these parameters, producers can optimize the oil yield and improve the product quality. For example, a study has shown that increasing the temperature within a certain range can accelerate the reaction rate, but excessive temperature may lead to oil degradation. Generally, a temperature between 80 - 100°C is recommended for most small - scale deacidification processes.

Pressure also has a significant impact on the deacidification process. Higher pressure can enhance the contact between the oil and the deacidifying agent, but it requires more energy and better equipment. A pressure of around 1 - 2 atmospheres is often a good balance for small - scale operations.

Time is another critical factor. Insufficient time may result in incomplete deacidification, while over - long processing time can cause unnecessary energy consumption and quality degradation. A processing time of 30 - 60 minutes is usually appropriate for small - scale palm oil deacidification.

Penguin Group's mini palm oil refining equipment comes with a PLC intelligent control system, which offers several advantages for small - scale producers. This system simplifies the operation process, reduces the risk of human error, and ensures consistent product quality. With the PLC system, producers can easily set and adjust the temperature, pressure, and time parameters according to their specific needs.

For example, if you want to optimize the oil yield, you can use the PLC system to precisely control the deacidification process based on the recommended parameter ranges mentioned above. This not only improves the efficiency but also reduces the waste of raw materials.

Besides deacidification, degumming, bleaching, and deodorization are also crucial steps. Degumming is used to remove phospholipids from the oil, which can improve the oil's clarity and stability. Bleaching helps to remove pigments and other impurities, giving the oil a lighter color. Deodorization eliminates unpleasant odors and flavors, making the oil more acceptable to consumers.

Here is a simple table summarizing the key points of these steps:

| Step | Purpose | Key Parameters |

|---|---|---|

| Degumming | Remove phospholipids | Temperature: 60 - 80°C, Time: 20 - 30 minutes |

| Bleaching | Remove pigments and impurities | Temperature: 90 - 110°C, Time: 20 - 30 minutes |

| Deodorization | Remove odors and flavors | Temperature: 200 - 240°C, Pressure: <1 mmHg, Time: 60 - 90 minutes |

Throughout the refining process, it's important to follow safety regulations and best practices. Regular maintenance of the equipment is also essential to ensure its long - term performance. In case of common problems such as low oil yield or poor product quality, this article provides practical solutions to help you quickly resolve these issues.

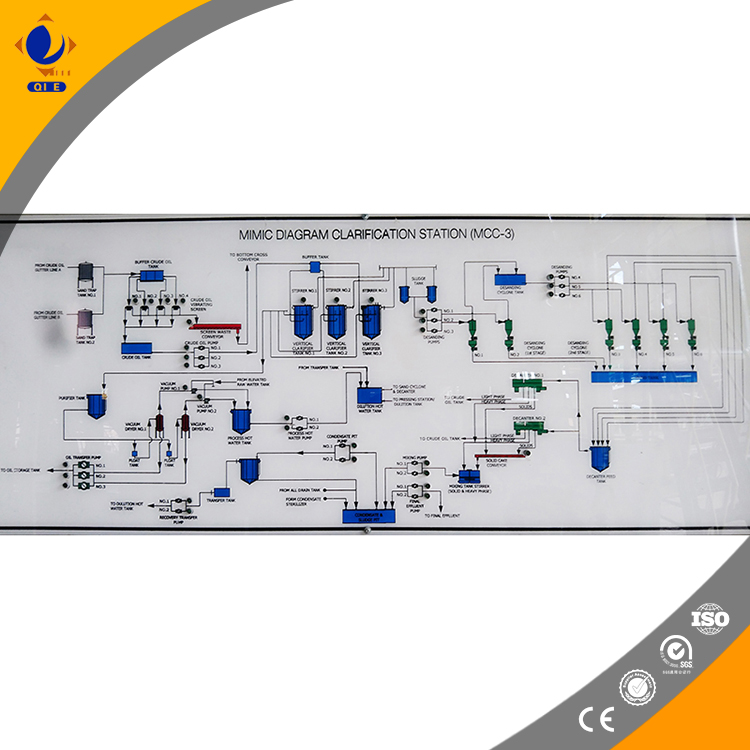

To further assist you in learning the refining process, we have provided a flowchart and an operation video. You can refer to these multimedia resources to better understand the steps and optimize your production.

Ready to enhance your small - scale palm oil production? Discover how Penguin Group's mini palm oil refining equipment can revolutionize your business. Click here to learn more